凯多智能科技(上海)有限公司致力于为橡胶轮胎行业的各个生产环节提供全面的智能解决方案。通过KADO定制服务,我们针对轮胎生产的压出、压延、裁断及成型等工序,提供精准而高效的纠偏、测厚、测宽、轮廓扫描及视觉检测等解决方案。

这些智能解决方案不仅助力轮胎制造生产线的自动化水平,更确保了产品质量的稳定性和一致性。作为轮胎行业的合作伙伴,凯多始终以客户需求为导向,为客户量身定制解决方案,满足个性化需求。我们不断吸收国际先进的生产技术和经验,提升产品在国际市场的竞争力。

Kaido Intelligent Technology (Shanghai) Co., Ltd. is committed to providing comprehensive intelligent solutions for all production links in the rubber tire industry. Through KADO custom services, we provide accurate and efficient solutions for deviation correction, thickness measurement, width measurement, profile scanning and visual inspection for the rolling, extrusion, forming and cutting processes of tire production.

These intelligent solutions not only assist in the automation level of tire manufacturing production lines, but also ensure the stability and consistency of product quality. As a partner in the tire industry, Kaido has always been customer-oriented, tailoring solutions to meet personalized needs. We continuously absorb advanced international production technology and experience to enhance the competitiveness of our products in the international market.

凯多智能科技(上海)有限公司自主研发的KADO视觉检测系统,为轮胎行业提供了高效且可靠的在线检测解决方案。该系统利用先进的图像处理技术和算法,能够实时捕捉材料表面的缺陷、异物、尺寸变化等问题,并即时提供准确的检测结果,针对轮胎生产线中不同材料的胎面、垫布等材料表面进行精准检测,有效确保产品质量和生产效率,避免次品产生,降低生产成本。

KADO visual inspection system independently developed by Kaiduo Intelligent Technology (Shanghai) Co., Ltd. provides an efficient and reliable online inspection solution for the tire industry. This system utilizes advanced image processing technology and algorithms to capture real-time defects, foreign objects, size changes, and other issues on the surface of materials, and provides accurate detection results in real-time. It accurately detects the surface of different materials such as tread and padding in the tire production line, effectively ensuring product quality and production efficiency, avoiding defective products, and reducing production costs.

系统采用C型或O型扫描架,配置一组传感器往复扫描测量物料厚度。扫描稳定性极高,适用于高精度测量。并可根据实际需求更改扫描模式分别为连续扫描、间隙扫描等;

The system adopts C-type or O-type scanning frame, equipped with a set of sensors to reciprocate scanning to measure the thickness of materials. The scanning stability is extremely high, suitable for high-precision measurement. The scanning mode can be changed to continuous scanning, gap scanning, etc. according to actual needs;

轮廓扫描系统采用点激光或线激光传感器在目标物上产生漫反射,通过检测位置、形状的变化来测量位移和形状。可应用于2D测量,可测量高度、高度差,宽度、位置、形状、截面、翘曲、平坦度等。

The contour scanning system uses a point laser or a line laser sensor to produce diffuse reflection on the target, and measures the displacement and shape by detecting changes in position and shape. Can be applied to 2D measurement, can measure height, height difference, width, position, shape, cross section, warpage, flatness, etc.

内衬层板条纠偏系统广泛应用于轮胎成型生产过程中,主要起到纠偏导正材料的功能。该系统具有精度高、稳定性好、无纠偏极限、不损伤材料等优点。

The lining strip correction system is widely used in the process of tire forming, which mainly plays the function of correcting the deviation and guiding the positive material. The system has the advantages of high precision, good stability, no deviation correction limit and no damage to materials.

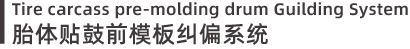

胎体贴鼓前模板纠偏系统主要作用是通过纠偏装置和传感器,对胎体的位置和方向进行精确控制,使其能够准确地贴合到成型鼓上,从而保证轮胎的质量和性能。

The main function of the tire front template correction system is to accurately control the position and direction of the tire body through the correction device and sensor, so that it can accurately fit on the forming drum, so as to ensure the quality and performance of the tire.

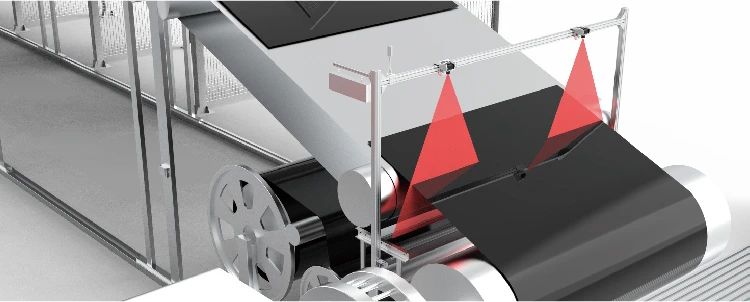

带束层纠偏系统采用先进的传感器技术和控制算法,能够实时监测带束层的位置和偏差情况,并自动调整纠偏装置,使带束层始终保持在正确的位置上。带束层纠偏系统的应用能够提高轮胎的质量和性能,降低废品率,提高生产效率,是轮胎制造过程中不可或缺的一部分。

Using advanced sensor technology and control algorithm, the system can monitor the position and deviation of the belt layer in real time, and automatically adjust the correction device to keep the belt layer in the correct position. The application of the belt correction system can improve the quality and performance of the tire, reduce the scrap rate and improve the production efficiency, which is an indispensable part of the tire manufacturing process.

感谢您的阅读,期待与您再次相聚,共同见证行业的创新与发展!凯多智能科技将持续引领橡塑产业的革新,为您提供更加先进、全面的智能检测解决方案。我们将继续努力,不断创新,期待与您携手共创辉煌!

Thank you for reading, and look forward to meeting you again to witness the innovation and development of the industry! Kaido Intelligent Technology will continue to lead the innovation of the rubber and plastics industry and provide you with more advanced and comprehensive intelligent testing solutions. We will continue to work hard, continuous innovation, look forward to working with you to create brilliant!